Most of our customers see the benefit of having checklists in SAP to support their inspection and maintenance process. There are different ways how these checklists can be set up in SAP, all with their pro’s and con’s. But the real challenge starts before you come to that point, when you try to fit all the puzzle pieces together.

Topics: Checklist, SAP Work Manager, SAM, smart asset management, MAM

Introducing SAM aka Smart Asset Management for SAP

Today we are happy and proud to announce the launch of SAM (Smart Asset Management), a new solution for making the work with SAP PM and CS easier. It is a mobile solution that is built on the currently best technologies on client, middleware and backend.

One way or another, we are mobilizing SAP’s plant maintenance and customer service since 2002. NetWeaver Mobile and MAM (Mobile Asset Management) have been the first generation of solutions. In 2010 we introduced MOMENTUM, a solution developed on top of the Sybase Unwired Platform - we sold it to a large German software vendor in 2011. Since 2012 we mainly implemented the SAP Work Manager, the latest generation of SAP’s mobile field service offering. Now in 2016 we once again launch our own solution - Smart Asset Management or short SAM.

Topics: MobiLink, Windows, Android, iOS, SAP, Checklist, offline, SAM, smart asset management

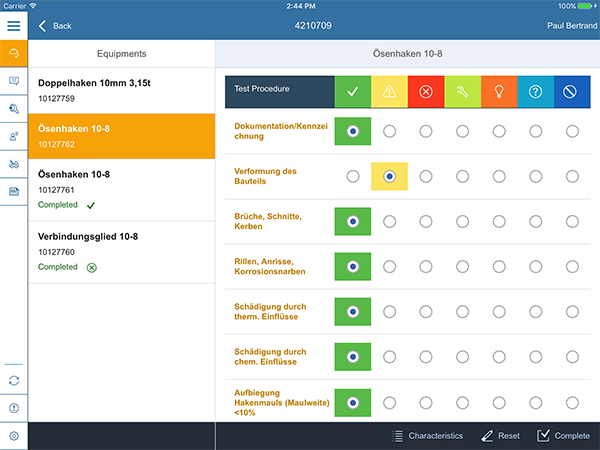

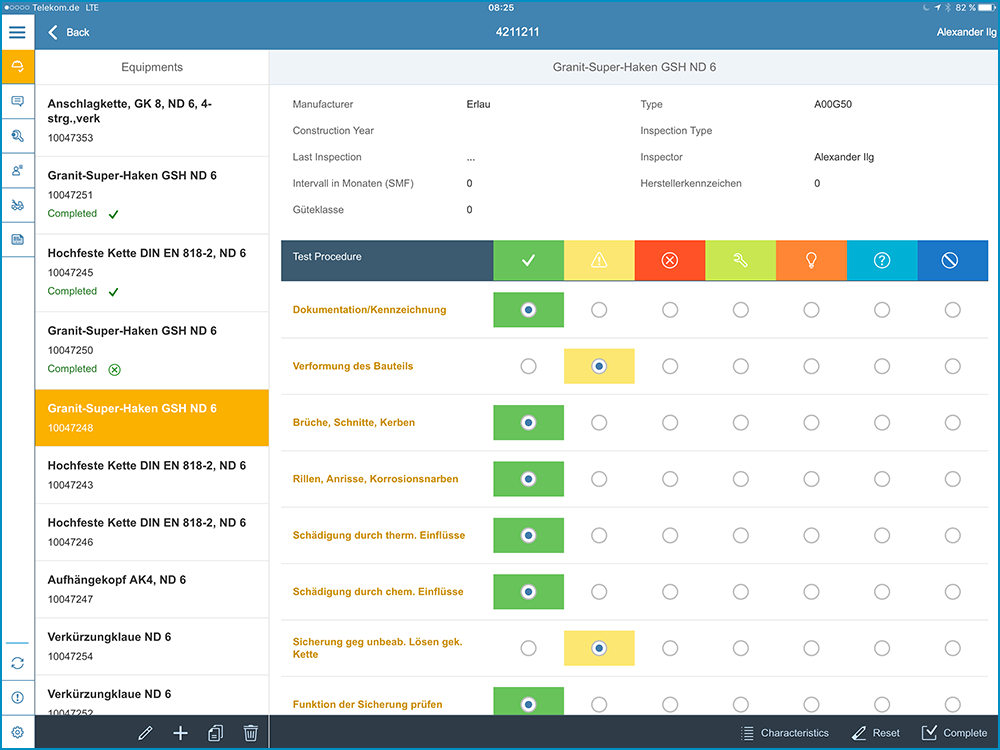

How to setup Checklists for Mobile Applications in SAP PM/CS

In a maintenance and customer service process, there are obvious domains to utilize checklists in order to fulfill the following purpose:

- Standardize maintenance checks based on predefined steps in order to ensure consistency and quality. As an example, we can examine a car inspection scenario which could consist of steps like:

- Check wheels

- Check engine

- Check gears

- Capture condition of equipments

- Qualitative: e.g. general condition like “good” or “bad”

- Quantitative e.g. air pressure, operating hours or temperature

- Capture standardized error codes and causes like “outworn”, “overheated” or “leaking” for further analysis

Topics: SAP, Checklist, Customer Service, Maintenance, SAP Work Manager, SAM