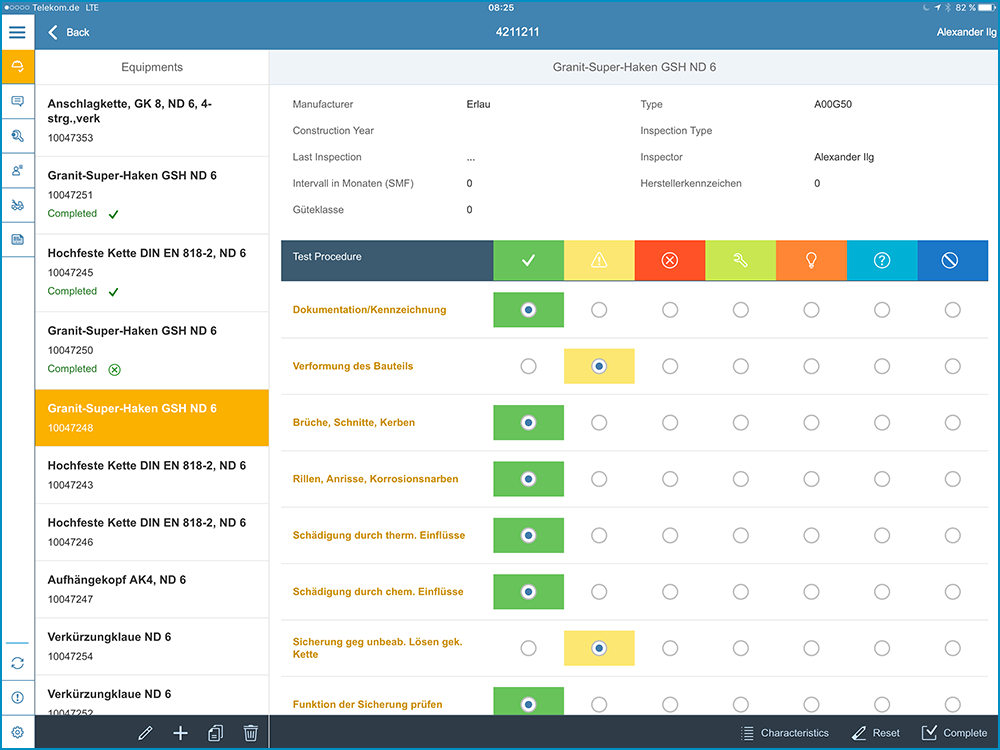

If well maintained, your SAP Plant Maintenance system should be the central point to get all information about your technical objects. General equipment data, characteristics, measurement points and their documents, notification and order history. But that is not all, some of the information that you want to store are binary data - issues are documented by making pictures or by taking a backup of the equipment’s software. For making the live of service technicians easier you want to provide documentation, technical drawings and other attachments.

When users access the SAP PM functionality via a mobile device - especially in an offline scenario - they need an efficient way to send these binaries both ways. With MobiLink, SAP offers a great tool that allows just that. It can be used to synchronize database tables, but also binaries independent from the database. This blog explains the basics of the FileTransfer feature and shows a customer example how it is used to synchronize large binaries in a customer service scenario.